Polyethylene (PE) Granules: Your Go-To Guide for Choosing the Right Plastic

From Bottles to Bulletproof Vests, It All Starts with These Tiny Pellets

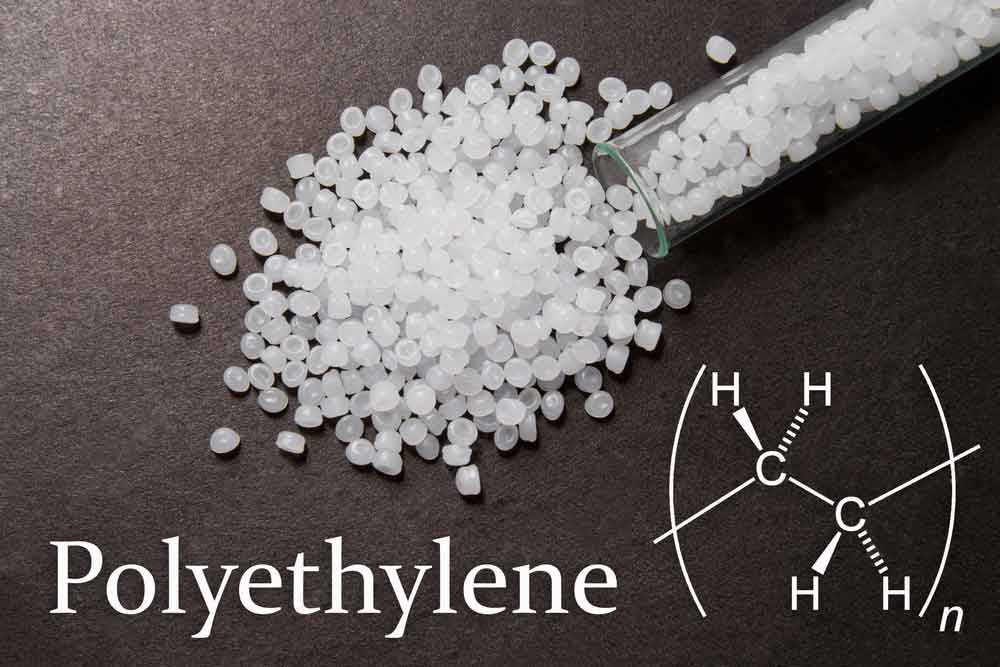

Ever wondered why a plastic milk jug feels so sturdy, while a shopping bag is soft and flexible? Or how a pipe can withstand pressure for decades without failing? The answer lies in one of the world’s most versatile materials: Polyethylene (PE). And it all begins with small, unassuming pellets known as polyethylene granules.

These granules are the building blocks of modern plastics. But not all PE granules are the same. Choosing the wrong type can lead to wasted resources, poor product performance, and higher costs.

This guide breaks down everything you need to know about PE granules—the science, the types, and how to choose the right one for your application. Whether you’re an engineer, a product designer, or a business owner, consider this your ultimate resource.

Part 1: What Exactly Are Polyethylene Granules?

Polyethylene is a polymer, meaning it’s made of long chains of repeating molecules. In this case, the molecule is ethylene (C₂H₄), a simple gas. Through a process called polymerization, thousands of ethylene molecules link together to form durable chains:

n(CH₂=CH₂) → [–CH₂–CH₂–] n

But here’s where it gets interesting: the structure of these chains determines the material’s properties. Chains that are straight and tightly packed create a rigid plastic, while branched and tangled chains make a softer, more flexible material. This structural difference is what gives us the diverse family of polyethylene types.

Part 2: Decoding the PE Family — HDPE vs. LDPE vs. LLDPE

High-Density Polyethylene (HDPE): Strong and Reliable

· Structure: Long, straight chains packed like neatly stacked logs.

· Properties: High strength, stiffness, chemical resistance, and durability.

· Best Uses:

o Water and gas pipes

o Milk jugs and detergent bottles

o Fuel tanks and chemical drums

o Toys and playground equipment

Low-Density Polyethylene (LDPE): Flexible and Transparent

· Structure: Highly branched chains, like a pile of tangled branches.

· Properties: Soft, pliable, transparent, and impact-resistant.

· Best Uses:

o Plastic films (shopping bags, food wrap, bubble wrap)

o Squeeze bottles and tubes

o Wire and cable insulation

o Flexible lids

Linear Low-Density Polyethylene (LLDPE): The Balanced Performer

· Structure: A linear backbone with short, controlled branches.

· Properties: Flexible yet strong, puncture-resistant, higher tensile strength than LDPE.

· Best Uses:

o Stretch films and pallet wrap

o Heavy-duty garbage bags

o Agricultural films

o Flexible tubing and irrigation pipes

Quick Comparison: HDPE vs. LDPE vs. LLDPE

|

Feature |

HDPE (Strong) |

LDPE (Flexible) |

LLDPE (Balanced) |

||||||

|

Chain Structure |

|

|

Linear with short branches |

||||||

|

Crystallinity |

High (>90%) |

Low (40-50%) |

Medium |

||||||

|

0.941–0.965 |

|

|

||||||

|

Strength |

High |

Low |

|

||||||

|

Flexibility |

Low |

Very High |

High |

||||||

|

Transparency |

|

|

Medium |

||||||

|

|

Films, bags, cables |

Stretch films, bags |

Part 3: Key Specs That Matter in Manufacturing

When sourcing PE granules, datasheets can feel overwhelming. Here are the most important factors simplified:

- Melt Flow Index (MFI): Indicates how easily the plastic flows when melted.

- High MFI → flows easily → best for injection molding (bottle caps, toys).

- Low MFI → flows slowly → best for extrusion (pipes, films).

- Density: Linked directly to rigidity and flexibility.

- Tensile Strength: Resistance to being pulled apart.

- Impact Strength: Ability to absorb sudden shocks without breaking.

Part 4: Virgin vs. Recycled Polyethylene Granules

With sustainability in focus, the choice between virgin and recycled PE granules is critical.

Virgin PE Granules

- Pros: Pure, consistent, reliable performance. Required for food packaging, medical devices, and high-spec applications.

- Cons: Higher cost, larger environmental footprint.

Recycled PE Granules

- Pros: Eco-friendly, cost-effective, reduces landfill waste.

- Cons: Less consistent, may contain impurities, slightly weaker properties.

👉 Bottom Line: Use virgin PE for sensitive, high-performance products. Use recycled PE for non-critical applications like trash cans, shipping pallets, or construction films.

Part 5: Where Polyethylene Granules Are Used

PE is everywhere in modern life:

- Packaging: Food wrap, stretch films, bottles, shopping bags.

- Construction: Corrosion-proof pipes, geomembranes, water tanks.

- Agriculture: Greenhouse covers, irrigation tubing, silage films.

- Automotive: Fuel tanks, bumpers, lightweight components.

- Consumer Goods: Toys, kitchenware, furniture, appliances.

Conclusion: Making the Right Choice

Polyethylene granules are far more than simple plastic pellets—they’re the foundation of countless products we use daily. By understanding the core differences between HDPE, LDPE, and LLDPE, and weighing the pros and cons of virgin vs. recycled materials, businesses can make smarter, more sustainable choices.

As innovation and sustainability continue to drive the plastics industry, polyethylene will remain a key raw material shaping industries worldwide.

Frequently Asked Questions (FAQ)

Q1:

What’s the difference between HDPE and LDPE?

HDPE is rigid and strong (like a milk jug), while LDPE is soft and flexible

(like a grocery bag).

Q2:

Which type of polyethylene is food-safe?

HDPE and LDPE are widely used for food packaging, provided they are certified

as food-grade.

Q3:

Is recycled PE as strong as virgin PE?

Not always—recycled PE usually has 80–90% of the strength of virgin material.

It’s excellent for non-critical uses.

Q4:

How can I identify polyethylene in products?

Look for recycling symbols: HDPE = #2, LDPE = #4. LLDPE is often unmarked but

used in films.

هیچ دیدگاهی برای این مطلب ثبت نشده است.