Polypropylene (PP) Granules: A Definitive Guide from Molecular Structure to Industrial Applications

Introduction: How Polypropylene Quietly Conquered the Modern World

In the vast universe of thermoplastic polymers, few materials command the same level of ubiquity and versatility as polypropylene (PP) granules. With a global production volume exceeding tens of millions of metric tons annually, this workhorse polymer has become a cornerstone of modern manufacturing. Its remarkable combination of physical, chemical, and mechanical properties has enabled its integration into a staggering array of products, from the food containers in our refrigerators and the dashboards of our cars to the sterile medical devices that save lives.

This article provides a comprehensive and expert analysis of polypropylene, delving deep into its scientific foundations and industrial significance. We will embark on a journey that begins at the molecular level, exploring its chemical structure, and culminates in its most advanced applications. Our goal is to furnish researchers, engineers, students, and industry professionals with a definitive resource that is both academically rigorous and practically invaluable.

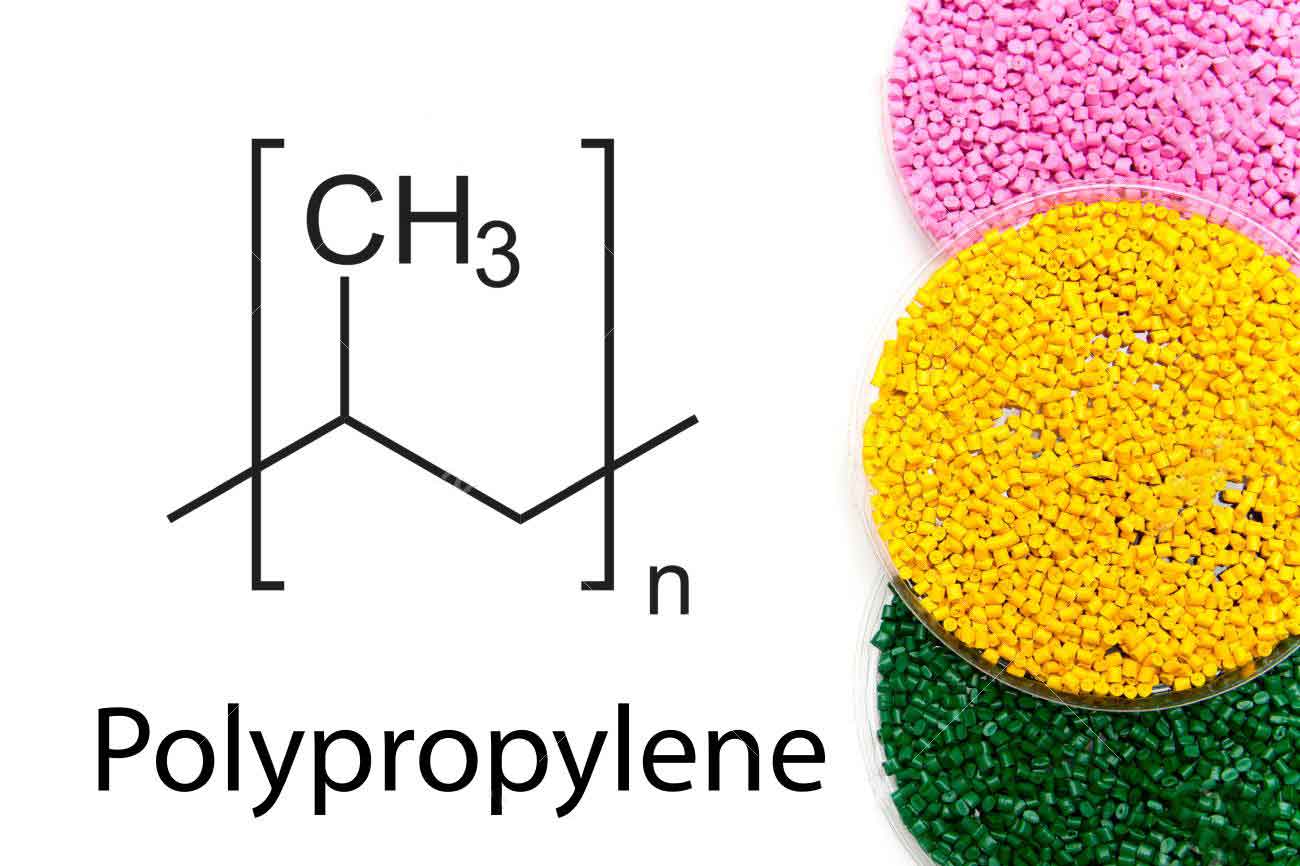

1. The Science of Polypropylene: A Look at Chemistry and Structure

Polypropylene is a linear hydrocarbon thermoplastic polymer derived from the polymerization of the propylene monomer (C3H6). This polymerization process is typically facilitated by advanced catalyst systems, most notably Ziegler-Natta or Metallocene catalysts. These catalysts are crucial as they offer precise control over the polymer s molecular architecture, a property known as tacticity.

The chemical backbone of polypropylene consists of a long chain of carbon atoms. Attached to every second carbon atom is a methyl group (CH3). The spatial orientation of these methyl groups along the polymer chain defines its tacticity, which profoundly influences the material's physical and mechanical properties. There are three primary forms of tacticity:

- Isotactic Polypropylene (iPP): All methyl groups are positioned on the same side of the polymer chain. This highly regular structure allows the chains to pack closely together, resulting in a semi-crystalline material with high crystallinity (typically 30-60%). Isotactic PP is the most common commercial grade, valued for its high tensile strength, stiffness, and excellent thermal resistance.

- Syndiotactic Polypropylene (sPP): The methyl groups are arranged in a regular, alternating pattern on opposite sides of the polymer chain. While also crystalline, sPP is generally more transparent and flexible than its isotactic counterpart. Its production is more complex, making it a specialty material.

- Atactic Polypropylene (aPP): The methyl groups are randomly distributed along the polymer chain. This lack of order prevents crystallization, resulting in an amorphous, soft, and rubber-like material with limited commercial use, often employed as a sealant or adhesive.

Therefore, when industry refers to polypropylene granules, it is predominantly discussing the highly ordered and exceptionally useful isotactic form.

2. Types of Polypropylene Granules: Selecting the Right Grade for Your Application

Polypropylene's true strength lies in its adaptability. By subtly altering the polymer chain, manufacturers produce distinct grades with tailored properties. The market for PP granules is primarily segmented into three major categories:

a) Polypropylene Homopolymer (PPHP)

This is the most widely utilized grade of polypropylene, consisting solely of propylene monomers. Its high crystallinity imparts a unique set of characteristics:

- High Strength and Stiffness: PPHP exhibits excellent tensile strength, making it ideal for structural applications.

- Superior Thermal Resistance: With a melting point of approximately 160-165 C, it can withstand high temperatures, making it suitable for applications requiring steam sterilization (autoclaving), such as medical equipment and microwave-safe containers.

- Excellent Chemical Resistance: It is highly resistant to a broad spectrum of acids, bases, and organic solvents.

Limitation: PPHP can become brittle at low temperatures, limiting its use in applications requiring sub-zero impact strength.

Common Applications: Textile fibers (carpets, upholstery), rigid packaging, strapping, sheet extrusion, and automotive components that do not face direct impact.

b) Polypropylene Copolymer (PPC)

To overcome the low-temperature brittleness of homopolymers, a secondary monomer typically ethylene is introduced during polymerization. This comonomer disrupts the crystalline structure, enhancing flexibility and impact resistance. Copolymers are further divided into two classes:

1. Random Copolymers (PPRC)

In this grade, ethylene units (usually 1-7% by weight) are inserted randomly along the polypropylene chain. This irregular structure reduces crystallinity and results in:

- Enhanced Transparency: The reduced crystallinity allows light to pass through more easily, making PPRC an excellent choice for clear packaging.

- Increased Flexibility: The material is softer and more pliable than PPHP.

- Lower Melting Point: This characteristic facilitates easier processing at lower temperatures.

Common Applications: Clear food containers, thin-wall injection molding (IML containers), blow-molded bottles, and pipes for hot and cold water systems.

2. Impact (or Block) Copolymers (PPBC / PPCP)

These materials are engineered with a more complex structure, where a rubbery ethylene-propylene copolymer phase is dispersed within a stiff polypropylene homopolymer matrix. This two-phase structure delivers a powerful combination of properties:

- Exceptional Impact Strength: These grades offer outstanding toughness and durability, even at very low temperatures (down to -40 C).

- Good Stiffness: They retain a significant degree of the rigidity characteristic of homopolymers.

- Excellent Fatigue Resistance: This makes them suitable for components subjected to repeated stress.

Common Applications: Automotive bumpers and dashboards, battery casings, luggage, industrial pails and crates, and heavy-duty consumer goods.

3. The Manufacturing Process: From Propylene Gas to PP Granule

The production of polypropylene is a sophisticated petrochemical process involving several key stages:

- Feedstock Preparation: High-purity propylene gas (C3H6), a byproduct of petroleum refining or natural gas cracking, is prepared as the primary raw material.

- Polymerization: The propylene gas is introduced into a reactor vessel along with a catalyst system. Under controlled temperature and pressure, the monomer units link together to form long polymer chains. The choice of reactor technology (e.g., gas phase, slurry, or bulk) significantly influences the final polymer properties.

- Purification and Deactivation: The resulting polypropylene powder is separated from unreacted monomers and catalyst residues, which are deactivated and removed.

- Compounding and Additivation: At this stage, the pure polymer powder is melt-blended with a carefully selected package of additives to enhance performance and durability. Common additives include:

- Stabilizers (Heat and UV): Protect the polymer from degradation caused by heat and ultraviolet radiation.

- Antioxidants: Prevent oxidation during processing and service life.

- Antistatic Agents: Reduce surface static charge to prevent dust accumulation.

- Pigments and Masterbatches: To produce colored granules.

- Reinforcements and Fillers: Such as glass fibers or talc to increase stiffness and strength.

- Extrusion and Pelletizing: The compounded mixture is fed into a twin-screw extruder, where it is melted, homogenized, and forced through a die plate to form spaghetti-like strands. These strands are immediately cooled in a water bath and cut into small, uniform cylinders known as granules or pellets.

These finished granules are the raw material shipped to manufacturers worldwide for conversion into final products via processes like injection molding, extrusion, and blow molding.

4. Scientific Analysis of Key Polypropylene Properties

Polypropylene's commercial success is rooted in its well-balanced property profile:

- Low Density: With a density ranging from approximately 0.90 to 0.91 g/cm , PP is one of the lightest commodity plastics, leading to significant weight savings in finished products.

- Chemical Resistance: Its non-polar, hydrocarbon nature makes it highly resistant to water, aqueous solutions of salts, acids, and alkalis.

- Thermal Resistance: PP homopolymer maintains its structural integrity at elevated temperatures, with a continuous use temperature of up to 120 C.

- Mechanical Properties: Polypropylene offers an excellent balance of stiffness, tensile strength, and flexibility. Its outstanding fatigue resistance is a unique attribute, allowing it to function as an "integral hinge" in applications like flip-top caps and storage containers.

- Electrical Insulation: As an excellent dielectric material, PP is widely used in electrical components and cable insulation.

- Processability: Its melt flow rate (MFR) can be precisely controlled, making it suitable for both high-speed injection molding and the extrusion of thin films.

5. Industrial Applications: Polypropylene's Pervasive Influence

The applications of PP granules span nearly every major industrial sector:

- Packaging: This is the largest single market for PP. It is used for rigid packaging (yogurt pots, butter tubs), flexible packaging (BOPP films for snack foods), and closures (bottle caps).

- Automotive: Driven by the need for lightweighting, the automotive industry uses PP extensively for bumpers, dashboards, interior door panels, battery cases, and air filter housings.

- Textiles: Polypropylene fibers are spun into yarns for carpets, rugs, ropes, and industrial fabrics. They are also used to create non-woven fabrics for diapers, sanitary products, and medical gowns.

- Consumer Goods & Appliances: The housings of vacuum cleaners, components in washing machines, kitchenware, toys, and outdoor furniture are all commonly made from PP.

- Medical & Healthcare: Thanks to its chemical resistance and ability to be sterilized, PP is a choice material for disposable syringes, labware, medical vials, and sterile packaging.

- Construction: Applications include pipes and fittings, septic tanks, fibers for concrete reinforcement, and geotextile membranes.

6. Environmental Considerations and The Future of Recycling

Polypropylene is identified by the recycling code #5. While not biodegradable, it is 100% recyclable. The mechanical recycling process involves collecting, cleaning, shredding, and re-melting PP waste to produce recycled polypropylene (rPP) granules. This rPP can then be used to manufacture new products like storage bins, park benches, pallets, and non-critical automotive parts.

Challenges remain in sorting and decontaminating post-consumer PP waste. However, significant progress is being made in advanced chemical recycling technologies. Furthermore, the development of bio-based polypropylene, derived from renewable feedstocks, represents a promising frontier for reducing the polymer's carbon footprint and dependence on fossil fuels.

Conclusion: The Enduring Value of Polypropylene

Polypropylene granules have rightfully earned their place as one of the most indispensable materials of the modern era. Their unparalleled versatility, low cost, and exceptional balance of properties ensure their continued dominance across countless industries. The ability to engineer its molecular structure into distinct homopolymer and copolymer grades provides designers and engineers with a powerful toolkit to solve complex material challenges.

As global demand grows for lightweight, durable, and cost-effective materials, the future of polypropylene looks exceptionally bright. Ongoing innovations in catalysis, the development of advanced PP-based composites, and a strengthening commitment to a circular economy will further solidify its role as a key engineering material for decades to come. For any industry professional, a deep understanding of the nuances of polypropylene is no longer just an advantage it is a necessity for innovation and success.

هیچ دیدگاهی برای این مطلب ثبت نشده است.